DPNS Racing Parts

DPNS Racing Parts is a specialist design and editor of accessories for racing motorcycles in the Netherlands. DPNS Racing Parts designs and manufactures all kinds of parts for different types of engines, such as road racing, dirt bikes and street fighter.

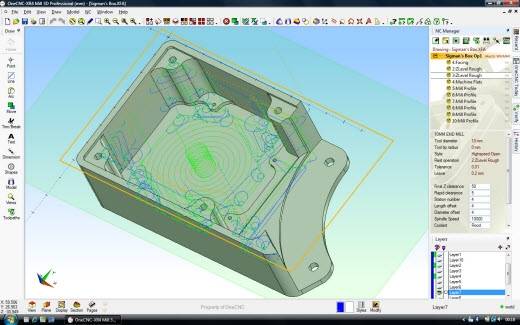

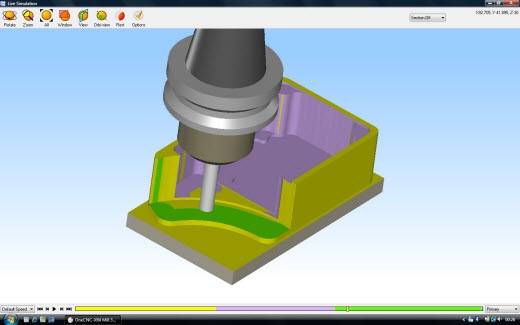

With an emphasis on design for production, but without compromising on style and aesthetics parts are modeled for in-house CNC machining.

With OneCNC XR5 for modeling and CNC programming are efficiently processed parts for CNC machining centers microns.

Here in the photos shown are the prototypes DPNS racing rear sets for the Ducati Panigale.

.jpg)

DPNS Racing Parts

Giant Mountains 3

BA 5508 Veldhoven

Netherlands

Email:

Website: www.dpns.nl

DPNS Racing is proudly powered by OneCNC Benelux support and if you want to be a part of OneCNC Benelux group of customers in the Netherlands, its contact:

OneCNC Benelux

Mierloseweg 40

5666 KA Geldrop

Netherlands

ph + 31 (0) 40 22 66 212

Fax + 31 (0) 40 22 40 794

E-mail:

Web: www.onecnc.nl

OneCNC Updates

OneCNC XR9 Release 74.80

Apr 01 2024

OneCNC XR9 Release 74.77

Feb 28 2024

OneCNC XR9 Release 74.68

Feb 13 2024