OneCNCXR3 at University of "Intelligent Robot Laboratory"

Tokyo Polytechnic University, "Intelligent Robot Laboratory" in collaboration with the private sector is conducting teaching research in a unique and extensive experience with research and development.

OneCNC Japan had previously supplied OneCNCXR3 and a visit was made to see how the software was involved in the production of parts in the laboratory. We spoke with Mr. Ikeda Ph.D, Research Associate and Mr. Yamaguchi who is in a masters course and discussed the work that was being performed by the laboratory using OneCNC.

Mr. Ikeda explained the main purpose of the introduction of OneCNC and CNC machining was "cost savings" which was necessary for the budget of the laboratory.

The laboratory also required shorter lead times in processing of the required parts.

We were surprised to find OneCNC so competitively priced for such a good product that included 3 dimensional simulation that we required.

We purchased OneCNC and found we could use it immediately after installation without any formal training. The OneCNC operation was easy to grasp and a very good user interface helped us to use it.

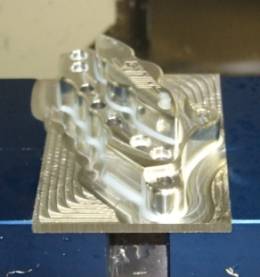

Mr. Yamaguchi explained that machining gear cases for example the tool paths has very smooth movements and short processing times.

Until the final shape is machined the HSM tool paths has such good constant load control that there are no part failures during the machining even on thin walled parts leaving the parts all left intact and accurate.

Mr. Ikeda said we first purchased OneCNCXR3 Mill Express and recognized it's value and soon decided to upgrade to OneCNCXR3 Mill Expert in one month.

Here are some covers for the submarine project the laboratory is building.

As a result of the introduction of OneCNC and NC machining it should pay for itself within a year and in this time provide many advantages for the future creating more efficient parts.

OneCNC and NC machining provides an important part of our research and development process which requires a lot of trial and error and extensive re-manufacture of items in the design process.

Dr. Ikeda (left) Mr. Yamaguchi, in masters course (right)

Profile:

Tokyo Polytechnic University "Intelligent Robot Lab".

1583 Iiyama Atsugi, Kanagawa Prefecture.

Research:

Robot leg formula (2 dimensional plane)

Robot leg formula (3 dimensional space)

Floating posture of robot control

Mobile underwater (submarine) control

Two robot dinosaur

URL: http://www.runbot.jp

OneCNC更新

OneCNC XR9 Release 74.93

七月 25 2024

OneCNC XR9 Release 74.90

七月 11 2024

OneCNC XR9 Release 74.83

四月 23 2024