A&A Machine & Development Company was started in 1972 by Eric Hymovitz’s father. Eric spent a lot of time at the shop, learning the trade and sweeping floors; ultimately taking over the business in 1995. Located in Gardena, CA, A&A Machine’s customers include the commercial and aerospace industries, working with materials such as aluminum, brass, bronze, stainless steel, carbon steel casting, forging and other exotic materials.

“As our CNC department grew I knew we needed to more powerful software programs. Moving from 2-2.5D into 3 & 4 axis, the availability of technical support, and the needs we were facing as a growing shop, I started doing my research. We made the switch to OneCNC and immediately felt productive with the software. I instantly appreciated the ease of use of OneCNC and the power that exists because of the ease of use. We started out on a lower level of OneCNC and in a short period of time we upgraded to simultaneous 5 axis, lathe, and wire EDM.”

The transition was smooth because of the help Eric received from OneCNC technical support, and the available training videos. Eric handles most of the programming in this 30 man shop, “sometimes you will run into a particular job and just not know how to tackle it, and I don’t have someone over my shoulder at the shop to provide me with the techniques that are best suited for a job, but with OneCNC’s technical support, you do have someone there to help with different methods that are effective for your parts. It is assuring that I have someone behind me to give me the confidence that I can do any job that comes across my desk. It helped develop and expand our shop because we were able to get into jobs that we might have been a little afraid of but because we have OneCNC behind us, we now know we are capable to take those jobs on."

“We just purchased another 5 axis machine in December which is exciting as our other 5 axis machine was always busy and behind schedule, we are looking forward to maximizing our capabilities this year. I know we are going to have a good year, in talking with my customers I know that they are going to have a good year. We are an integral supplier for our customers and will continue to be for a long time to come, these relationships and their opinions of our reliability is valuable to the success of A&A Machine”.

Mr. Eric Hymovitz

For more information please visit: www.onecnc.com and www.aamach.com

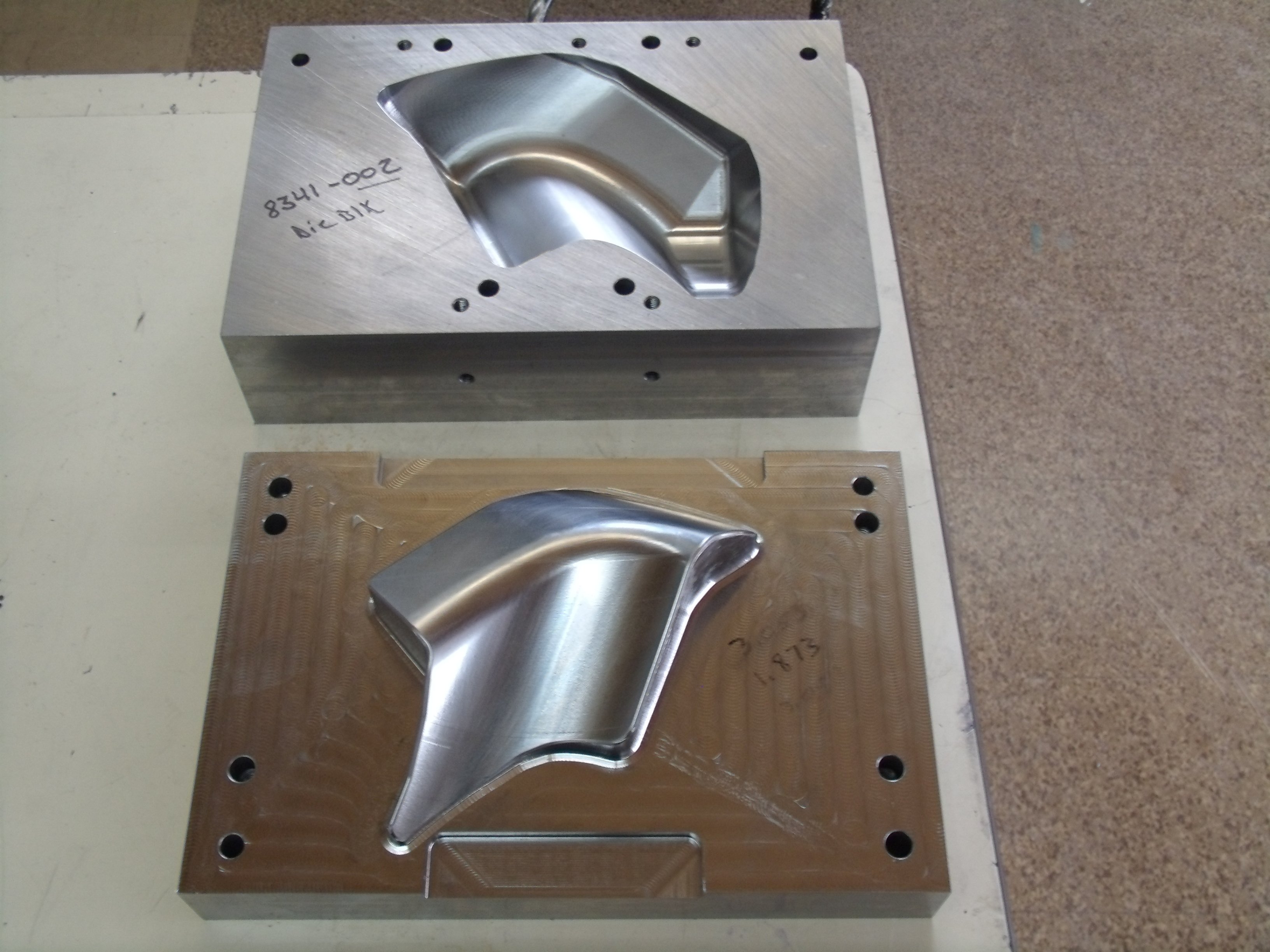

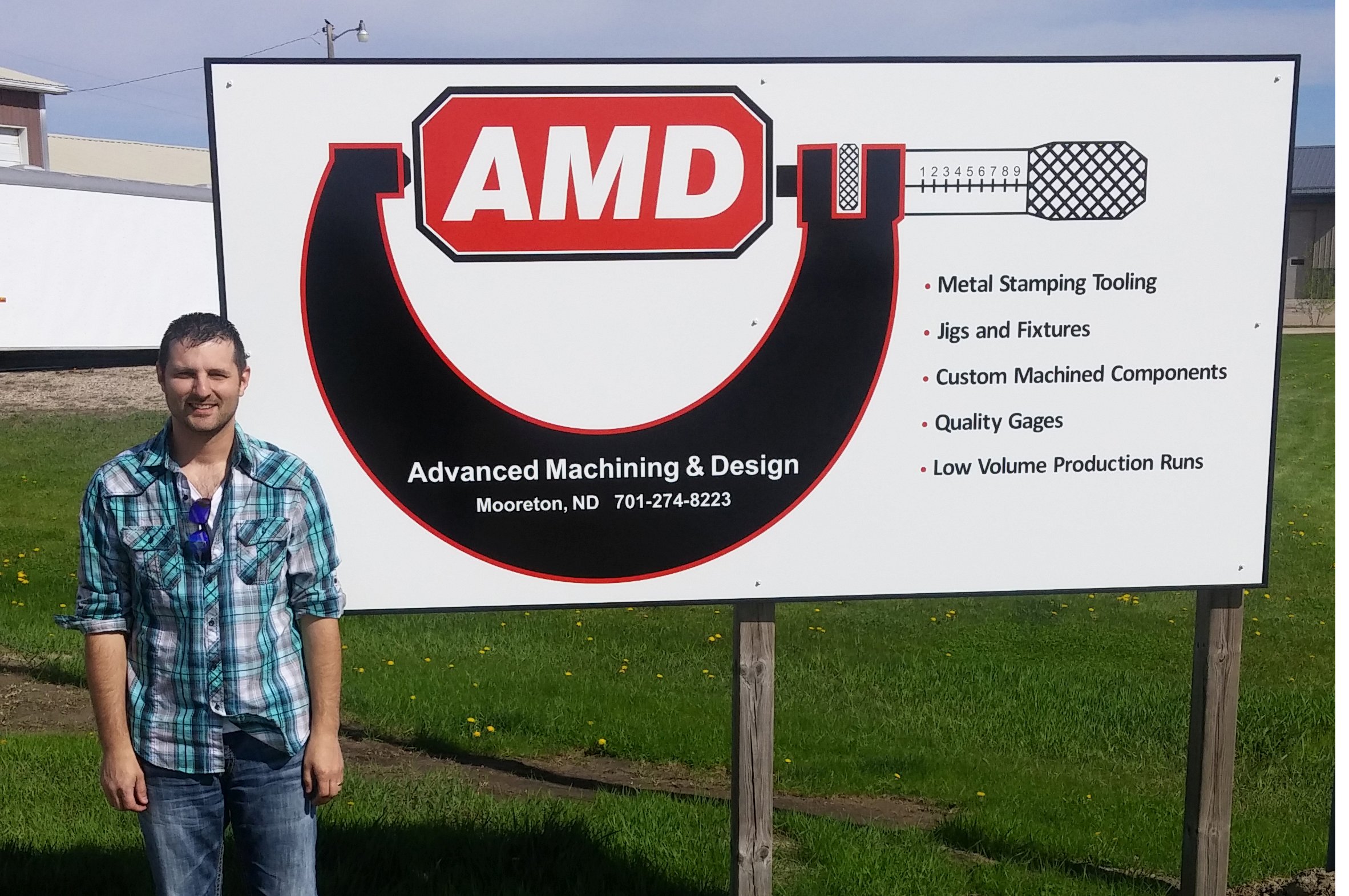

Advanced Machining & Design, Mooreton, ND – USAAdvanced Machining & Design is a machine shop with experiences in design, manufacturing, and machining of quality parts for the construction, agriculture and aerospace industries. Owner, Chris Berndt, started Advanced Machining & Design in 2011 by renting a small garage size space and purchasing a Haas CNC mill. In 2016 he built a new facility and expanded adding on an additional Haas CNC mill, Fanuc wire EDM, and a Hurco CNC lathe.

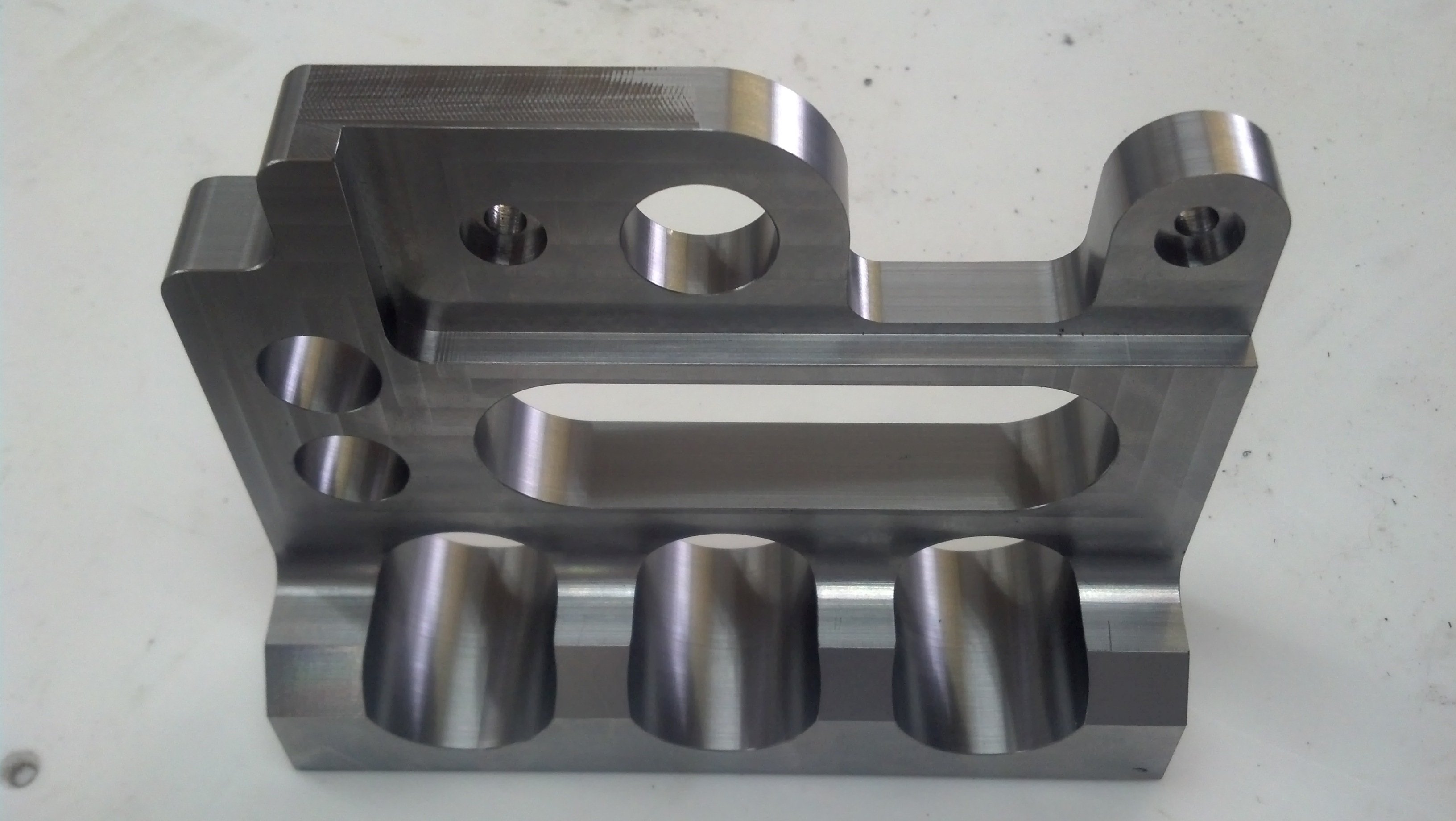

Chris’ extensive knowledge in machining allowed him to build his core business around automation equipment builds, tooling (blanking, progressive, forming dies), and machine fixturing projects.

“Prior to operating my own business, I worked for a major window producing company. Holding position as a Tool and Die Maker, then moving into leadership roles as Tooling Manager and eventually to the position of Manufacturing Engineering Manager. Through this development, I have been able to combine skills, with strategic planning and design.”

Chris decided that he wanted to do 100% of his programming in CAM software, he knew the best way to streamline and maintain accuracy was to focus on a CAM program that would give him the ability to be efficient saying, “I actually set up my business in part around my software decision.”

“When first going through the process of evaluating CAM systems I looked at many possibilities. My customers provide me with the part designs nearly every time. So, I determined I need to focus on finding a CAM package that was capable, cost effective and easy to learn.”

“I do 100% of my programming on OneCNC and none at the machine tool itself. OneCNC has been a major part of my business success and is vital to my business. The software went above and beyond my expectations and I have since upgraded 4 different times and do so every time a new version comes out. I am confident OneCNC is constantly staying on top of the latest and greatest technologies curve and that is something that is extremely important to me. This is a competitive business and I need to be able to make the highest quality parts as efficiently as possible and OneCNC does just that for me, It has been one of my absolute best business decisions yet to date.”

After his recent upgrade to XR7, Chris has been very happy with the new additions, “I do some very intricate geometries and I have yet to come across any part that I was not able to produce at an extremely high level of quality. It also utilizes very efficient tool paths. The Z level roughing (high speed machining) has saved me countless dollars in tooling and removes material extremely efficiently and the finishing toolpaths leave a beautiful finish.”

Advanced Machining & Design has grown every single year because they can answer the demands of their customers in today’s competitive market. “Without a tool like OneCNC, I would have struggled to produce at the level I do and deliver on such short lead times. I enjoy the challenges that come with running my own business and I always have growth in mind and look forward to hiring another employee this year.”

Hargett Precision Products & HPP SimulationHargett Precision Products and HPP Simulation owner Mark Hargett, has always loved designing and building things. In 2006 after growing tired of corporate politics where he worked Mark decided to purchase a CNC. Mark says, “I started a project of restoring an early Porsche 911 and knew I wouldn’t be able to build the parts I wanted for it with a hacksaw or hammer, which is why I bought a new Hurco CNC Mill, and put it in my garage.” After learning his Hurco, he knew it was time to purchase CAM software and after evaluating many different systems, Mark decided OneCNC was the best choice for his new business. “Being new to CNC, I realized I needed a CAM program to help me utilize my CNC from CAD to machining. I cannot think of a CAM program I didn’t evaluate, I came across OneCNC and the intuitive interface, the simplicity and capability were awesome from the perspective of a new end user, nothing compared to it. Purchasing OneCNC allowed me to get more comfortable and efficient with the manufacturing process enabling us to grow into a successful business and purchase additional CNC equipment with multi axis capability.”

Specializing in older and high performance Porsches, Mark created a successful line of shifters and pedals for the 911s, Indy and off road racing. The success of Hargett Precision allowed Mark to expand into another area which is designing and building components for high end race car simulators (HPP Simulation). Machined out of 6061T6 aluminum, these hydraulic pedal systems are designed for sim racing. Sim racing has become somewhat of a worldwide phenomenon, but the industry lacked simulators that replicated the true feel of race car pedals. “We machine and manufacturer almost everything on the entire set, so we use OneCNC a lot in the production of them.”

“I enjoy being creative and designing my own products in my own way, and I enjoy that people want my products, I like that I cannot make these products fast enough. The future of Hargett Precision Products and HPP Simulation will see additional streamlining, new part designs and productions, and a lot of growth.”

Hargett Precision Products/ HPP Simulation

Vista, CA